Best Automotive Wheel Bearing Greases: Complete Selection Guide

Understand wheel bearing grease requirements

Automotive wheel bearings operate under extreme conditions that demand specialized lubrication. These critical components endure constant rotation, heavy loads, temperature fluctuations, and exposure to water and contaminants. The right grease selection straight impact bear longevity, vehicle safety, and maintenance costs.

Source: indiamart.com

Wheel bearings require grease that maintain its consistency across wide temperature ranges while provide excellent water resistance and load carry capacity. The lubricant must besides resist oxidation and provide long term protection against wear and corrosion.

Types of wheel bearing greases

Lithium complex greases

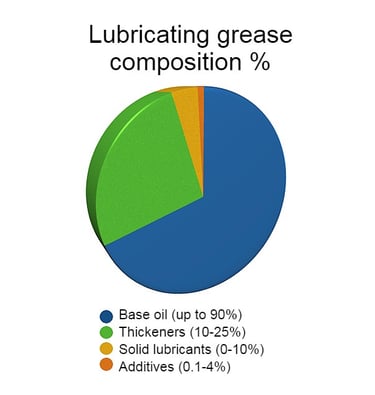

Lithium complex greases represent the near popular choice for automotive wheel bearings. These formulations offer exceptional thermal stability, operate efficaciously from 40 ° f to 350 ° f. The complex soap structure pprovidessuperior water resistance compare to simple lithium greases.

Key advantages include excellent pumpability at low temperatures, high dropping points, and strong mechanical stability. Premium lithium complex greases oftentimes incorporate synthetic base oils for enhanced performance in extreme conditions.

Polyuria greases

Polyuria grease excel in high temperature applications and provide outstanding oxidation resistance. These synthetic thickener systems maintain consistency regular under severe thermal stress, make them ideal for heavy-duty applications and performance vehicles.

The non soap thickener structure offer superior water washout resistance and excellent compatibility with seals and elastomers. Polyuria greases typically command higher prices but deliver extended service intervals.

Calcium sulfonate complex greases

Calcium sulfonate complex greases provide exceptional corrosion protection and water resistance. The unique thickener chemistry create a protective barrier that prevent rust formation flush in marine environments.

These greases offer excellent load carry capacity and maintain their protective properties in the presence of water contamination. They’re specially suitable for vehicles operate in harsh environmental conditions.

Critical performance characteristics

Temperature range

Wheel bearing greases must function across automotive temperature extremes. Cold weather performance affects startup torque and bear protection during initial operation. High temperature stability prevent grease breakdown and oil separation under heavy loads or extended operation.

Quality wheel bearing greases typically operate from 30 ° f to 300 ° f, with premium formulations extend these ranges. Synthetic base oils enhance both low and high temperature performance.

Water resistance

Water contamination represent a primary cause of bear failure. Effective wheel bearing greases resist water washout while maintain their lubricate properties when moisture enters the bear cavity.

ASTM d1264 water washout testing measures this critical property. Superior greases lose less than 10 % of their mass during standardized water spray testing, ensure continued protection in wet conditions.

Mechanical stability

Wheel bearings subject grease to continuous mechanical working that can break down the thickener structure. Automatically stable greases maintain their consistency and protective properties throughout extend service intervals.

ASTM d217 work penetration testing evaluate mechanical stability by measure consistency changes after extended mixing. High quality wheel bearing greases show minimal penetration changes, indicate stable performance.

Lead grease formulations

Premium synthetic blends

Top tier wheel bearing greases combine synthetic base oils with advanced thickener systems. These formulations deliver superior performance across all critical parameters while extend service intervals.

Synthetic blends typically incorporate polyalphaolefin (pPAO)or popolyalkenelycol ( pa()PAG) oils for enhanced thermal stability and oxidation resistance. The higher cost is offset by extended service life and superior protection.

High temperature specialty greases

Performance and heavy-duty applications demand grease capable of withstand extreme thermal conditions. These specialized formulations utilize synthetic base oils and advanced thickener systems to maintain protection at elevated temperatures.

Racing and commercial vehicle applications benefit from greases with dropping points exceed 500 ° f and continuous operating temperatures above 300 ° f. These formulations prevent bear failure under severe operating conditions.

Marine grade formulations

Boat trailers and vehicles operate in coastal environments require enhanced corrosion protection. Marine grade wheel bearing greases incorporate corrosion inhibitors and provide exceptional water resistance.

These specialized formulations resist saltwater corrosion while maintain their lubricating properties in wet conditions. They’re essential for trailers often submerge during boat launch and retrieval.

Application specific considerations

Passenger vehicle requirements

Standard passenger cars and light trucks benefit from high quality lithium complex greases that provide reliable protection under normal operating conditions. These applications prioritize cost-effectiveness while maintain adequate performance.

Modern seal bearings in passenger vehicles require greases with extended service life and compatibility with various seal materials. The grease must remain stable throughout the bearing’s intend service interval.

Commercial vehicle demand

Heavy-duty trucks and commercial vehicles subject wheel bearings to extreme loads and extended operating periods. These applications require premium greases with superior load carry capacity and thermal stability.

Commercial vehicle greases must withstand the constant stress of heavy loads while provide protection during extended highway operation. Synthetic formulations oftentimes prove cost-effective despite higher initial costs.

Performance vehicle applications

Sports cars and performance vehicles generate significant heat during aggressive driving. High performance wheel bearing greases must maintain their protective properties under extreme thermal conditions.

Track day and racing applications demand greases with exceptional high temperature stability and minimal consistency change under stress. These specialized formulations prevent bearing failure during competitive driving.

Compatibility and mixing considerations

Grease compatibility

Mix incompatible greases can result in consistency changes, reduced performance, or complete lubrication failure. Different thickener systems may not blend decent, create hard or soft mixtures that fail to protect bearings.

When change grease types, complete removal of exist lubricant ensure optimal performance. Compatibility charts help identify safe mixing combinations when complete clean out isn’t practical.

Seal compatibility

Modern wheel bearing assemblies incorporate various seal materials that must remain compatible with the select grease. Incompatible combinations can cause seal swelling, hardening, or deterioration.

Source: maconresearch.com

Quality wheel bearing greases undergo extensive seal compatibility testing to ensure long term performance with common elastomer materials. This testing prevent premature seal failure and contamination entry.

Installation and maintenance best practices

Proper application techniques

Correct grease application ensure optimal bearing protection and service life. Over greasing can cause excessive heat buildup and seal damage, while under greasing lead to inadequate lubrication and premature failure.

Fill bear cavities to roughly 30 50 % capacity, allow space for grease expansion and movement. Pack grease soundly into roller and race contact areas while avoid excessive quantities that impede bear rotation.

Service interval guidelines

Regular grease replacement maintains bear protection and prevents contamination buildup. Service intervals depend on operating conditions, grease quality, and manufacturer recommendations.

Severe service conditions include frequent water exposure, extreme temperatures, or heavy loads require more frequent grease replacement. Monitor bear temperature and noise levels to identify potential lubrication issues.

Quality standards and certifications

Industry specifications

Reputable wheel bearing greases meet establish industry standards that verify performance characteristics. NLG ((ational lubricating grease institute ))lassifications provide consistency ratings, while astASTMecifications define performance requirements.

Look for greases meet GC lb specifications for automotive wheel bearing applications. These standards ensure adequate performance across critical parameters include temperature range, water resistance, and mechanical stability.

Manufacturer approvals

Original equipment manufacturer (oOEM)approvals indicate that greases meet specific vehicle requirements. These approvals provide confidence in product performance and warranty compliance.

Major automotive manufacturers maintain approve lubricant lists that specify suitable greases for their vehicles. Follow these recommendations ensure optimal performance and maintain warranty coverage.

Cost-effectiveness analysis

Initial cost vs. Long term value

Premium wheel bearing grease command higher prices but oftentimes deliver superior long term value through extend service intervals and enhance protection. Calculate total cost of ownership include labor and potential failure costs.

Synthetic and semisynthetic formulations typically justify their higher cost through extend service life and reduce maintenance frequency. Commercial applications specially benefit from premium grease performance.

Failure prevention economics

Wheel bearing failure costs extend far beyond replacement parts to include labor, towing, and potential safety consequences. Quality grease selection represent insurance against these significant expenses.

Consider the cost of roadside assistance, lose productivity, and potential accident liability when evaluate grease options. Premium lubricants provide valuable protection against these risks.

Environmental and disposal considerations

Environmental responsibility include proper grease selection and disposal practices. Biodegradable formulations reduce environmental impact while maintain performance standards.

Use grease require proper disposal through authorized recycling facilities. Many automotive service centers accept use lubricants for proper processing and environmental protection.

Select greases from manufacturers commit to environmental stewardship and sustainable practices. These companies oftentimes provide superior products while minimize environmental impact.